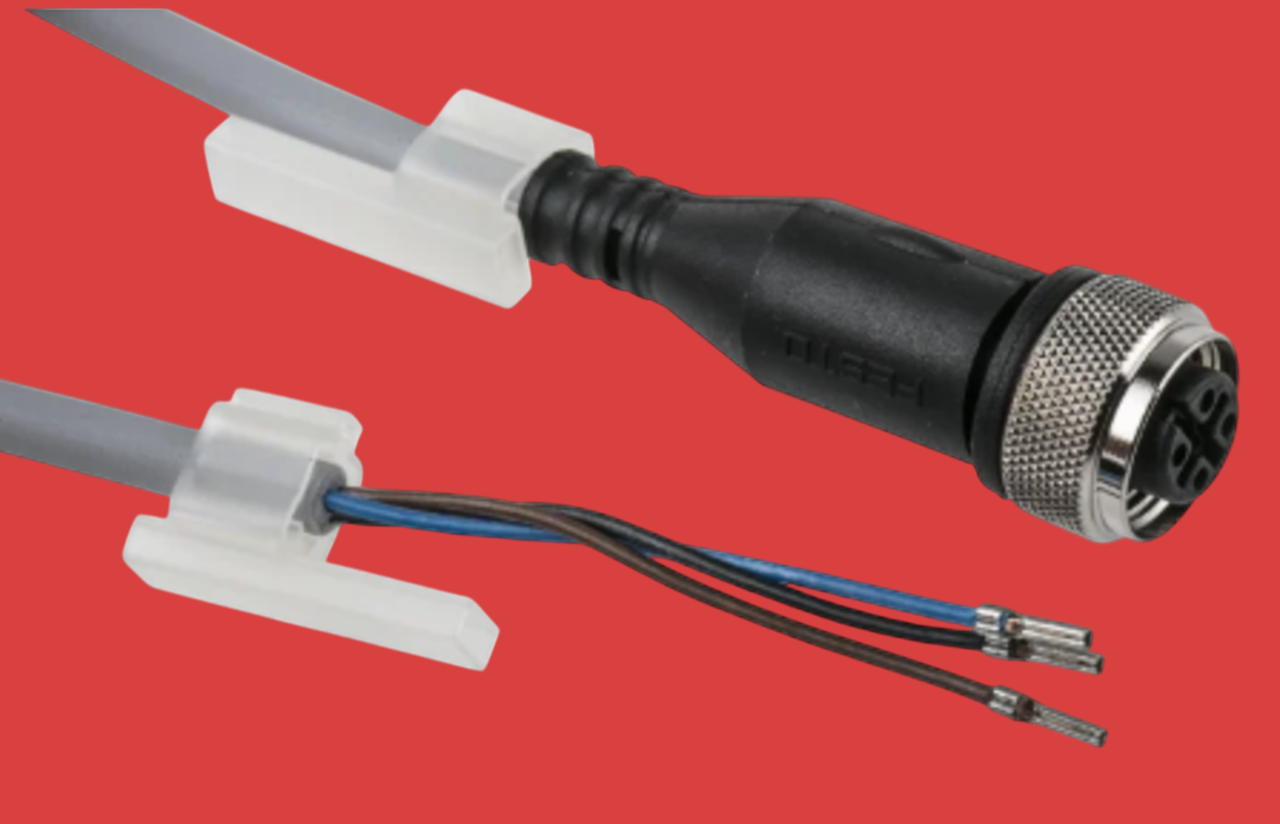

Connecting cable NEBA-M12G5-U-2.5-N-LE4

Connecting cable NEBA-M12G5-U-2.5-N-LE4

The Connecting Cable NEBA-M12G5-U-2.5-N-LE4 is a high-quality connection solution used in textile automation systems. It is designed to link sensors, actuators, and control units, ensuring smooth communication and reliable operation of machines. In modern textile factories, proper connections are very important because machines like dyeing units, weaving machines, and automated conveyors depend on accurate signals for efficient functioning.

In textile dyeing machinery parts, this connecting cable plays a key role in transmitting data from sensors that monitor pressure, temperature, or flow. It ensures that controllers receive accurate information to maintain correct dyeing conditions, leading to consistent fabric quality and reducing errors. The cable is durable, resistant to wear, and can handle industrial environments with exposure to moisture, heat, or chemical vapors often found in textile dyeing plants.

The NEBA-M12G5-U-2.5-N-LE4 is easy to install, flexible, and compatible with standard M12 connectors. Its reliable performance helps textile manufacturers improve machine efficiency, reduce downtime, and maintain smooth automation processes.

OVERVIEW

The Connecting Cable NEBA-M12G5-U-2.5-N-LE4 is an essential component in textile automation systems, designed to ensure reliable connections between sensors, actuators, and control units. In automated textile factories, seamless communication between machines is crucial for consistent operation, and this cable provides a stable and durable link that supports accurate signal transmission.

In textile dyeing machinery parts, the cable is used to connect sensors that monitor critical parameters like pressure, temperature, and flow. Accurate data transfer allows controllers to adjust dyeing processes in real time, ensuring uniform fabric quality and preventing production errors. The cable’s robust construction makes it resistant to industrial challenges such as heat, moisture, and exposure to chemical vapors, which are common in dyeing plants.

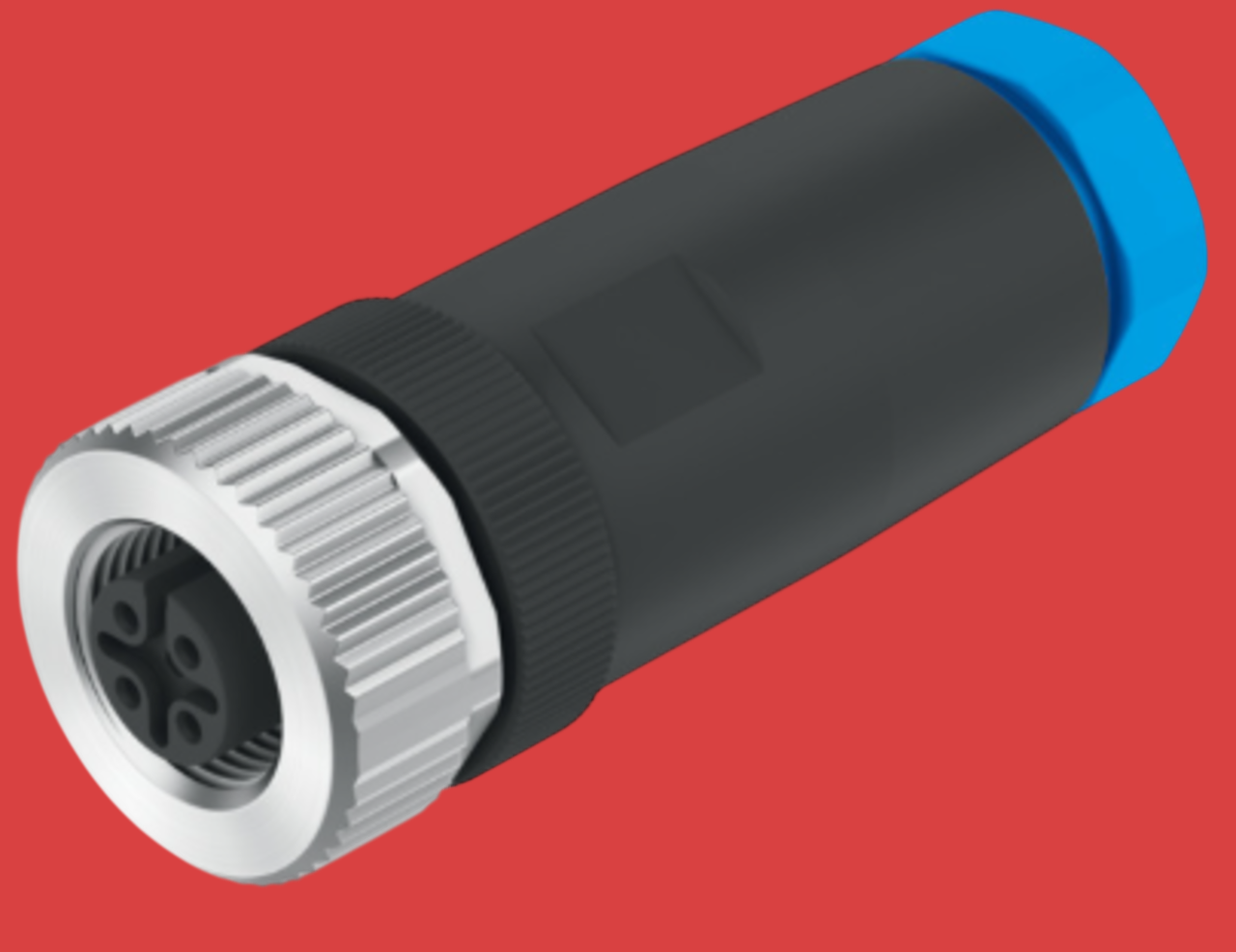

The NEBA-M12G5-U-2.5-N-LE4 features a standard M12 connector, making installation quick and straightforward. Its flexibility and high durability make it suitable for complex machine layouts and continuous operation. Using this cable improves machine efficiency, reduces downtime, and enhances the reliability of automated textile processes, making it a trusted choice for modern textile manufacturers.

SPECIFICATION

Connector: M12×1‑A coded female socket on field‑device side (round, straight outlet)

Number of pins/wires: 5 total cores, 4 active wires (standard colour coding: Pin 1 = BN, Pin 2 = WH, Pin 3 = BU, Pin 4 = BK)

Cable length: 2.5 metres (standard version)

Conductor cross‑section: 0.25 mm² (4 × 0.25 mm²)

Sheath / housing material: TPE‑U (PUR) with grey sheath, black housing; contacts are gold‑plated copper alloy.

Protection / Ingress Rating: IP65, IP68, IP69K — dust‑tight, water‑resistant, and capable of resistance under high‑pressure, high‑temperature wash‑downs (useful for harsh industrial environments).

Electrical rating: Up to 4 A at a maximum open‑circuit voltage of 30 V DC for energy‑limited circuits (as per manufacturer’s recommendation).

Environmental / mechanical robustness:

Operating temperature range: –40 °C to +85 °C (storage and fixed installation); for flexible / moving cable use: –20 °C to +85 °C.

Cable diameter: approx. 4.5 mm

Tested for high mechanical stress: torsional resistance > 300,000 cycles; bending fatigue resistance > 50,000 cycles (bending radius as low as 5 mm) — good for moving parts, conveyor‑type or robot arms.

Standards compliance: EN 61076‑2‑101 and EN 61984. UL‑listed (certificate UL E253748) for safety.

FEATURES

The cable uses a standard M12×1 A‑coded connector on the field‑device side, making it compatible with many sensors and actuators used in automation.

It has a 5‑wire construction (4 active cores) with 0.25 mm² conductors, enabling reliable signal or power transmission in typical control circuits.

Built with a durable TPE‑U (PUR) sheath, this cable is abrasion‑resistant, oil‑resistant, UV‑resistant, hydrolysis‑resistant, and ozone‑resistant — suitable for tough industrial environments often found in textile dyeing plants.

It offers high protection ratings — IP65, IP68, IP69K — meaning it resists dust, water spray, and even high‑pressure washdowns, which is handy in dye houses or humid factories.

The cable is flexible and robust: able to withstand torsional stress over 300,000 cycles and bending fatigue more than 50,000 cycles, making it reliable in moving machine parts or conveyor‑based automation.

It is suitable for both static installation and dynamic applications (like robotics, conveyors or moving dyeing machinery parts), giving textile plant designers flexibility in layout.

ENQUIRY NOW